At CK Power Family of Companies, collaboration is at the core of what we do. One of our strongest collaborations is between our Terramac and Hayes divisions. Hayes has long been a trusted supplier of powertrain components for Terramac’s innovative carrier designs. Though this relationship began before we became a unified entity, it continues today because of the high quality and reliable performance of Hayes products.

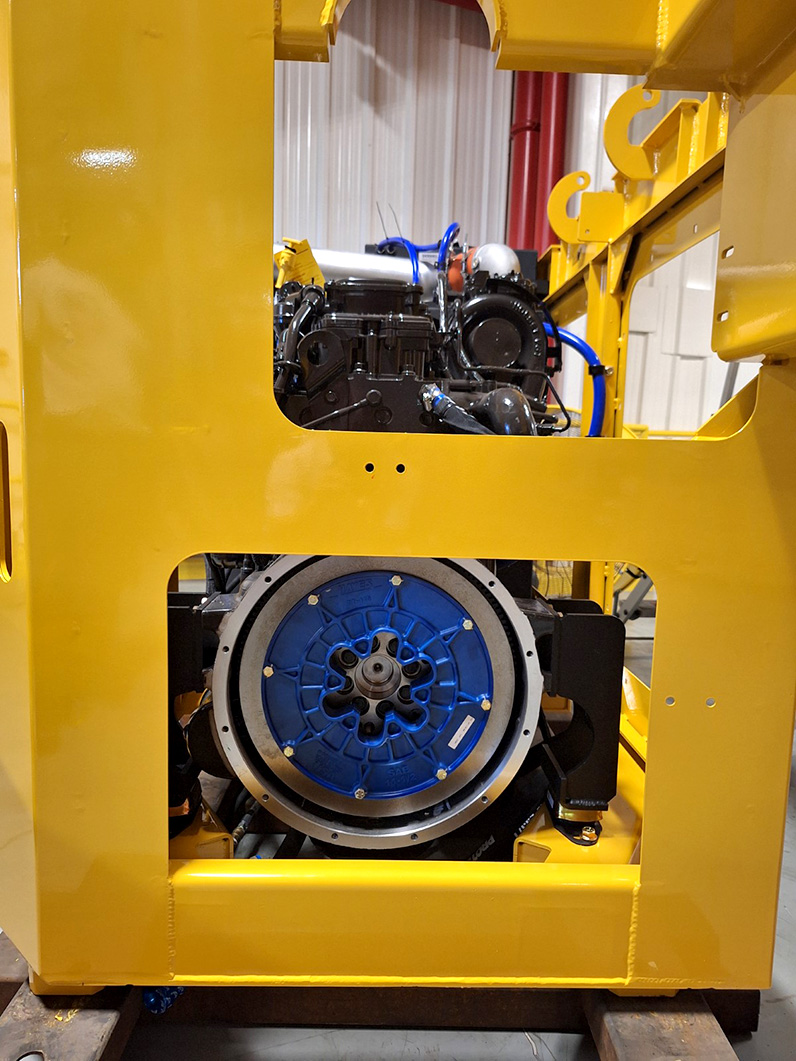

A prime example of this relationship is the Hayes coupling, a key component that connects Terramac’s Cummins engine and hydraulic pumps in each of their rubber tracked crawler carrier models. This coupling is meticulously engineered to provide efficient power transfer and minimize wear, which is crucial for maintaining the operational efficiency and reducing long-term maintenance costs of the carriers. This ensures that customers can rely on their tracked units for extended periods, with fewer repairs, resulting in greater productivity in the field.

“The durability and precision of Hayes couplings have been key in optimizing our rubber tracked product line’s overall performance. It’s a component we rely on for its consistency and reliability.”

– Tim Klaus, Terramac VP of Engineering and Operations

By combining the strengths of both divisions, we not only produce products that reflect our commitment to quality, but we also streamline our manufacturing processes. One of the key benefits of this collaboration is that, with Hayes and Terramac working under one umbrella, we’ve reduced reliance on external supply chains. This gives us greater control over quality, lead times, and overall consistency.

Keeping these processes in-house results in fewer delays, enhanced coordination, and a seamless flow from design to manufacturing, which leads to faster delivery times for our customers. In an industry where supply chain disruptions can severely impact timelines, our ability to produce essential components internally gives us a competitive edge, allowing us to deliver reliable products on time, every time.